Re:flex–Intuitive and resilient design at its best

by Purva Chawla

The Context

Almost unanimously, we are fascinated with materials or objects that appear to alter or move by themselves. This wide-eyed interest can be traced back to our childhoods, where magnets were mysterious, and robots were supreme. Stepping back, natural elements like leaves, petals, and roots are timelessly alluring for us, because of how they move towards and away from external stimuli strategically.

Beyond being a captivating sight, the world relies on materials that can adapt to different situations, and through independent movement or transformation, trigger essential mechanisms. Representing this realm perfectly is a class of materials known as Shape-Memory Materials (SMMs). These are 'smart' materials that can change from a temporary shape to a memorized permanent one upon the application of an external stimulus. This stimulus can often be thermal–a simple change of temperature–where the material can be distorted and deformed into any shape needed when it is pliable or cold, but when it reaches a set temperature the material returns once more to its memorized shape. SMMs can be metal alloys or polymers, or even hybrids of the two–an emerging class within Shape-Memory Materials.

Where do the unique powers of such materials come in handy, you ask?

The answer is, in countless, unseen and yet critical applications. SMMs behave as actuators in hydraulic mechanisms; they aid deployable structures and morphing wings in Aerospace engineering; they ensure the workability of medical devices like stents and assist in bone fracture healing. They even prevent scalding water from exiting our shower heads and serve as the backbone of fire protection systems, among dozens of other uses.

However, this class of materials remains expensive, hard to work with, and from a designer's perspective, somewhat elusive and out of reach. The many scientific applications of SMMs are rarely made visible or attractive in everyday life, and their aesthetic and functional potential has not been exploited or brought to the fore nearly enough when it comes to design products and objects.

Re:flex, an Intuitive Solution

In response to this context, and to these limitations, a young group of designers from the Innovation Design Engineering program at the Royal College of Art and Imperial College have invented Re:flex– a reconfigurable, programmable composite that changes its shape in response to heat.

Material samples, all Images courtesy Re:flex

The attractive material–which has a translucent shell and a brightly colored core– draws its inspiration from nature, namely the flexibility and resiliency that living, natural materials have. Natural materials and structures continually respond and adapt to changes in the environment, making them resilient, while our built environment and products are more static, rarely morphing in response to changing conditions. Instead, the team behind Re:flex notes, they are often discarded simply because of a need for minor adjustments.

The interdisciplinary team behind Re:flex–Karlijn Sibbel, Pierre Azalbert, Benton Ching and James Fraser–were determined to create a more responsive material, one that allows users to make an adjustment to everyday objects, increasing their lifetime and durability. At the same time, given the pace of change and the continuously shifting needs of users today, the goal, it seems was to allow multiple users to customize and then use the same object, which builds a case for the sustainability of objects made with Re:flex.

The resulting, flexible and thermally activated Re:flex is a low cost, widely available and more sustainable shape-memory material that can be manufactured at low temperatures on a large scale. Not only is the material intuitive in its behavior, but the applications and design products envisioned for Re:flex are equally intuitive and seem to offer plausible, yet highly attractive solutions to the challenges we face as designers and consumers today.

What is Re: Flex made of

So what is this material made of, and how does it behave in various circumstances:

Re:flex is a true shape-memory composite, which remembers the form it was made in. Users are able to heat it, deform it into a temporary shape they require and then cool it down to freeze it in place. When heated again, it returns to its original pre-memorized shape.

The composite is made of two components, a flexible translucent shell and a brightly colored core with higher stiffness. Despite being able to exhibit shape-memory properties, Re:flex is not made of conventional shape memory materials, rather it belongs to a new class of SMMs known as hybrids, whose properties arise from the interaction between two materials that do not ordinarily exhibit the effect. The temperature range and speed at which the composite operates can be adjusted by varying the composition and geometry of the inner material.

A composite made of two components, all Images courtesy Re:flex

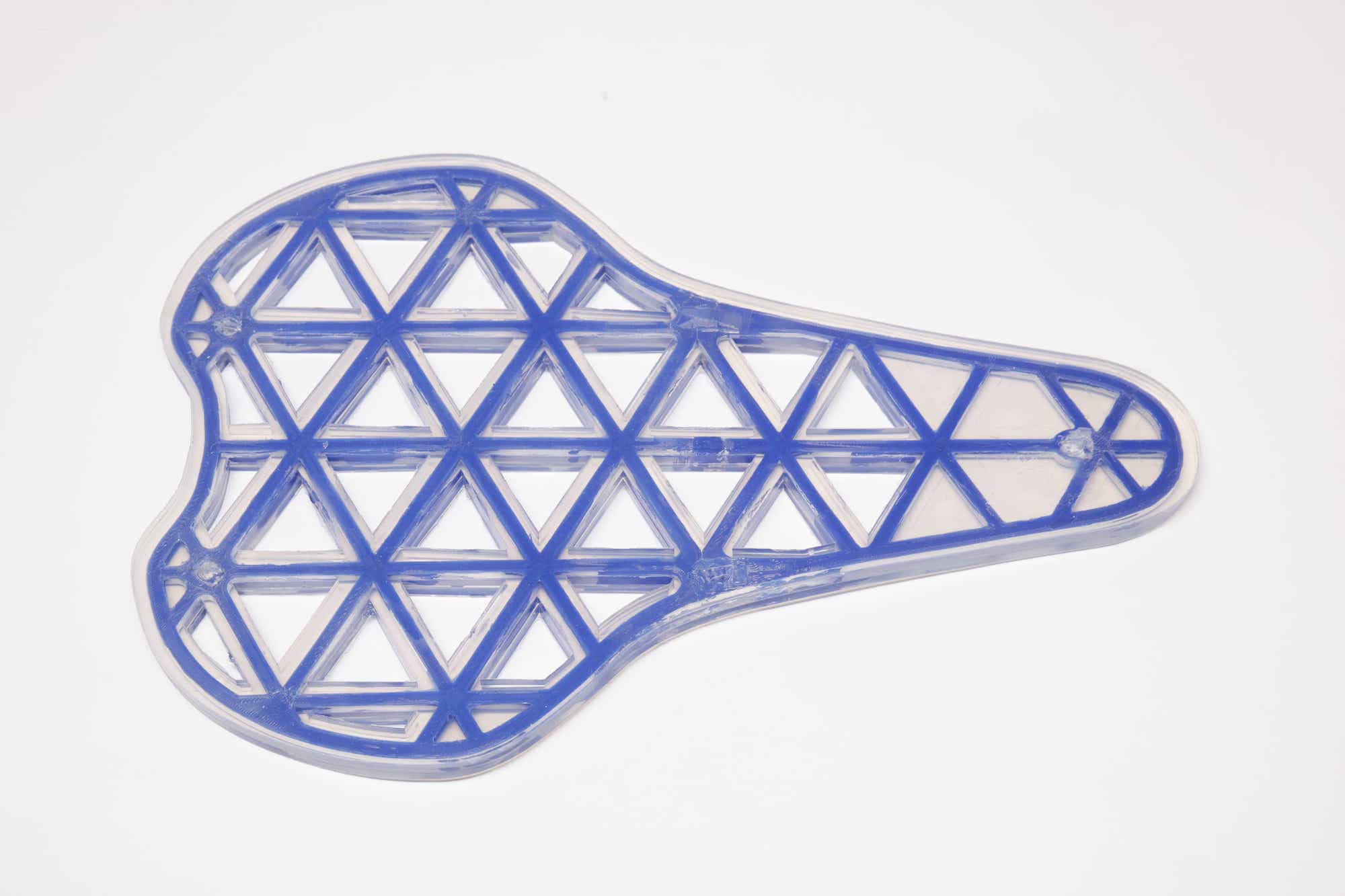

Bicycle saddle made with re:flex material, all Images courtesy Re:flex

A huge USP for us is this: These two components of Re:flex are not chemically bonded, which means that they can be easily separated for reuse and recycling at their end of life, improving the material’s circularity.

The exciting design potential of this material hinges on 3 core capabilities.

Reversible Fixation: The material can freeze in place at room temperature (a vital thing to note), allowing it to provide rigidity and structure to external elements. This fixation can be reversed with ease on the application of heat and used again for another purpose.

Thermal Actuation: It has the potential to be used as a thermal actuator within a more significant mechanism or system, providing force and motion to other components. Possibilities include soft robotics, medical devices, thermal valves, and switches. It can also generate enough force by itself to deploy folded sails, move robotic end effectors and self-assemble complex structures.

Unlimited Fitting: The flexibility and programmability of Re: flex allows it to conform to different surfaces, taking on new forms when it cools. This makes it a cost-effective and ergonomic solution with immense possibilities.

Design Potential

The team behind Re:flex has picked up on a few familiar design objects to illustrate the possibilities that this material holds. Each example highlights the versatility and practical value of the material and represents the three core properties that guide the manufacture of this material.

The first, the idea of a plaster arm cast which needn’t be used for a single person and then discarded, holds immense value. Not only relevant across multiple users, but this is also valuable for each user as well. Those who have had limbs in casts will understand how much adjustment is needed throughout the healing itself–with patients graduating from rigid casts to removable ones, to adjustable slings along the way. A cast made of Re:flex can potentially be disinfected, deformed, adjusted, and used again. Add to that the fact that it has an attractive appearance, which certainly betters the experience of wearing a cast.

Seen below, prototype arm cast made with re:flex.

The second application illustrated by the Re:flex team is that of flat-packed furniture, where a furniture joint made from the material that can be deployed with heat. Rather than assembling a piece of furniture bit by bit, a piece of flat-packed furniture unfolds just through the application of heat. Think of the hours saved!

Furniture joints made with re:flex material, all Images courtesy Re:flex

Finally, a bicycle saddle created by them illustrates the unlimited flexibility and programmability that Re:flex stands for. The saddle can be made more comfortable and contoured to a user's body, just by heating and distorting the surface. A great feat for a traditionally uncomfortable piece of cycling equipment!

This range of applications feels like the tip of what is possible with a material like Re: flex. Its aesthetic potential and ease of use compared to other SMMs out there bodes well for extensive application and success. What will be crucial, going forward, will seeing if the material can indeed be produced at low-cost and at large scales, allowing users as varied as children and medical professionals to access and benefit from it.